WRAP TRAP

"Wrap it up"

2_edited.png)

Why Wrap with a Wrap Trap

Manaul

01 / RELIABLE

Finding labor in any business can prove to be challenging, especially when the business has operations that are highly repeatable and can be automated. The Mad Flatter automates the process of preparing 1/2 flats for berries and can be customized for many other types of boxes.

02 / SAFE

Integrated with a safety system, the Mad Flatter makes it difficult for an operator to unknowingly put themselves in an unsafe situation. The use of safety switches, relays, and light curtains on access points of the machine help mitigate the risk of dangerous situations.

03 / EFFICIENT

At 4-6 seconds per fully folded and pinted flat, the Mad Flatter outpaces up to 6 average personnel manually doing the same job. With the Mad Flatter, you can keep other work going when flats need to be produced.

Integrated with a safety system, the Mad Flatter makes it difficult for an operator to unknowingly put themselves in an unsafe situation. The use of safety switches, relays, and light curtains on access points of the machine help mitigate the risk of dangerous situations.

THE WRAP TRAP

"Let us wrap it for you"

In partnership with Columbia River Staple, Unger Designs developed a machine to realize a concept presented to by Columbia River Staple. This machine, still in development, can auto detect lumber units, auto select and dispense the appropriate wrap, and automatically wrap the entire unit with minimal controls movements and without the need for complex robotics.

01 / AUTO WRAP SELECT

This machine starts by monitoring incoming lumber units and measuring its width and height, followed by calculations of the appropriate wrap. The dispenser then indexes the wrap to the right roll and feeds it into the machine.

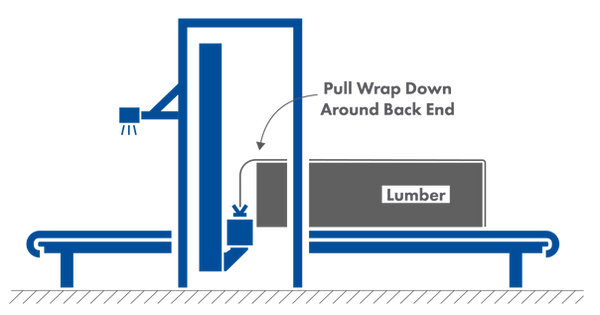

02 / WRAP PULL DOWN

The machine then stops the lumber unit right in front of the wrap, grabs the wrap from the dispenser, and pulls it down to begin wrapping.

03 / FRONT SIDE STAPLE

The machine then indexes the sides of the wrap and the front of the unit in sync to pull the wrap tight around the front of the unit, then staples it down.

04 / DETECT UNIT LENGTH

Further indexing of the unit forward results in a detection of the length of the unit when the sensors on the front of the machine detect the absence of a unit. This is used to calculate the length of wrap required.

How this works

05 / CUT WRAP AND PULL OVER BACK

The wrap is then cut by the dispenser and pulled down to the back of the unit for the back side wrap.

06 / STAPLE BACK END

The unit is then conveyed backwards to repeat the same in sync wrap and staple as the front. There are two arms that pop up and hold the wrap in place in order to lay properly.

07 / GANG STAPLE SIDES

After the wrap is placed on the unit, the gang stapler is moved down to the top of the unit, closed to press the wrap down, then moved down to the bottom of the unit to stretch the wrap over the unit.

08 / FEATURES

The Wrap Trap consists of two machines, the Wrap Trap Dispenser and the Wrap Trap Wrapper. The Wrap Trap Dispenser includes the following features,

-

an indexer and 6 roll bays to hold up to 6 different wrap rolls.

-

Roll width guides to hold and guide wrap widths from 60" to 120".

-

Wrap edge locators to automatically guide the wrap into the machine.

-

Roll driver mechanism to connect and disconnect driving the rolls for indexing and dispensing.

-

Side to side alignment mechanism to align the wrap to the unit.

-

Cutter to cut the wrap.

The Wrap Trap Wrapper includes the following features,

-

Grabber arms that are able to find the edge of the wrap or the edge of the unit, grab onto the wrap, pull the wrap tight and down, and staple the wrap to the unit.

-

Variable speed conveyor designed to move the unit to any location at controlled speeds within the machine.

-

Front end sensors to measure the size of the unit.

-

Gang Stapler with 8 staplers configured to pull the wrap down and staple both sides of the unit.